Basic Info.

Model NO.

FWSW-2X1

Inserting Loss

<1dBm

Reflection Loss

>55dBm

Polarization Dependence

<0.1dBm

Repeatability

<0.02dBm

Switch Time

<10ms

Switch Option

2X1

Type of Optical Connector

FC/APC, Sc/APC or Specified by The User

Fiber Type

Single Mode

Transport Package

Case Packing

Specification

CE, RoHs, ISO

Trademark

FULLWELL (OEM available)

Origin

Zhejiang, China

HS Code

8517622990

Production Capacity

8000PCS/Month

Product Description

Optical Switch 2X1

(FWSW-2X1)

(FWSW-2X1)

1.Introduction

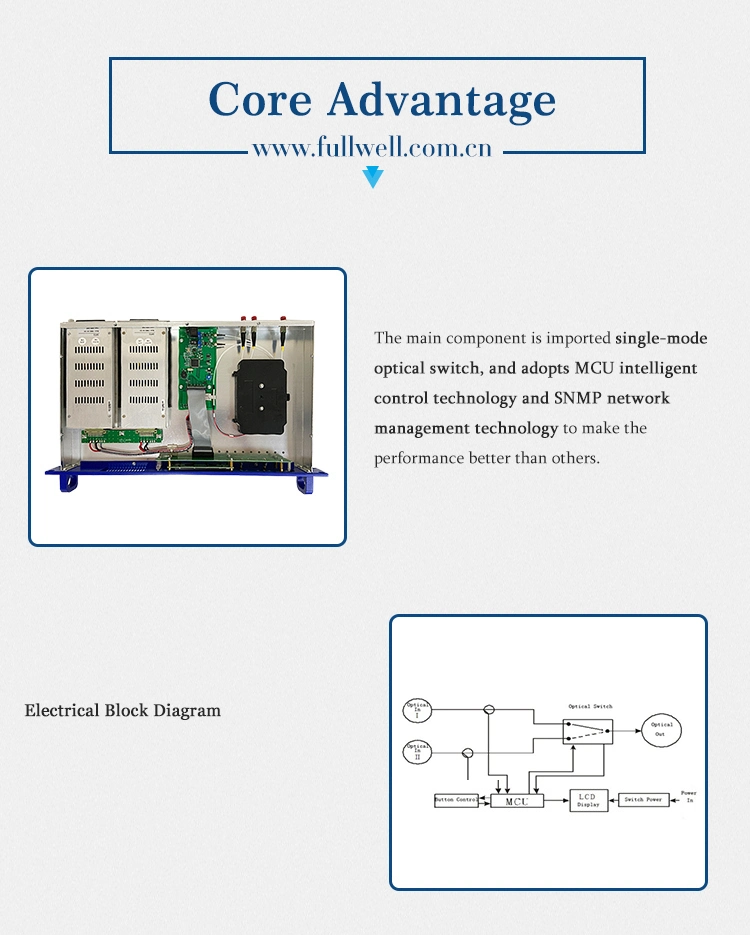

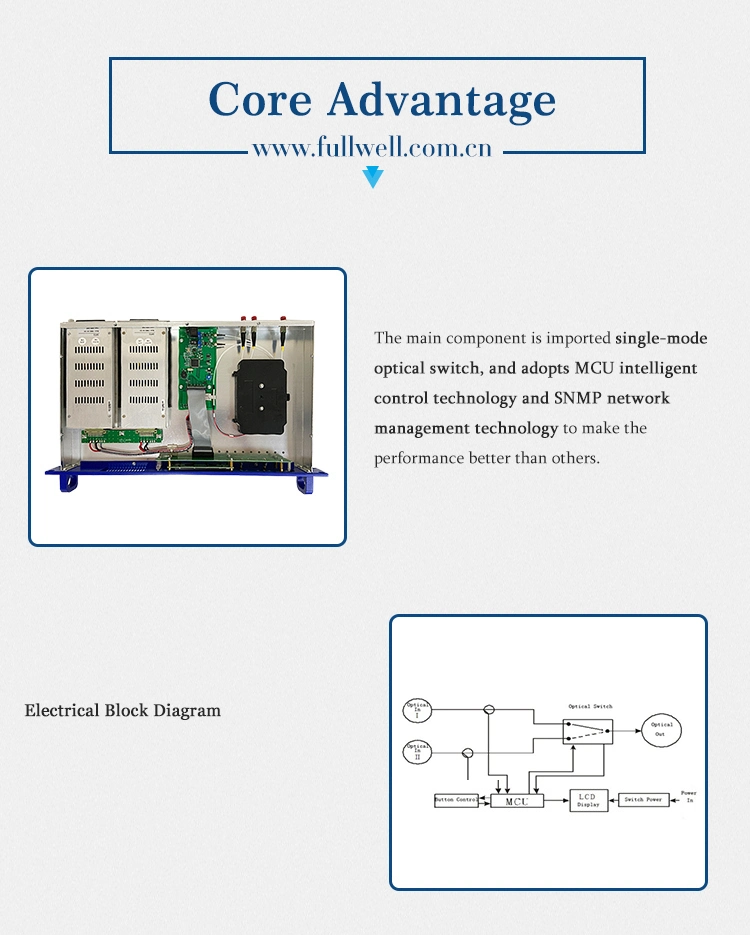

FWSW-2x1 optical path selector (commonly known as an optical switch) is mainly used as the protection mechanism of optical fiber networking in optical networks. In addition to low loss, it provides a good switching design in terms of an optical switch, making the switching speed of the optical switch lower than 10ms. At the same time, considering whether the optical signal RF signal monitoring and automatic switching and alarm. The front panel LCD section will provide real-time QAS monitoring parameters and alarm information, as well as some functions and parameters that can be set. In addition, the front panel LED indicator light provides a real-time alarm display.

2.Features

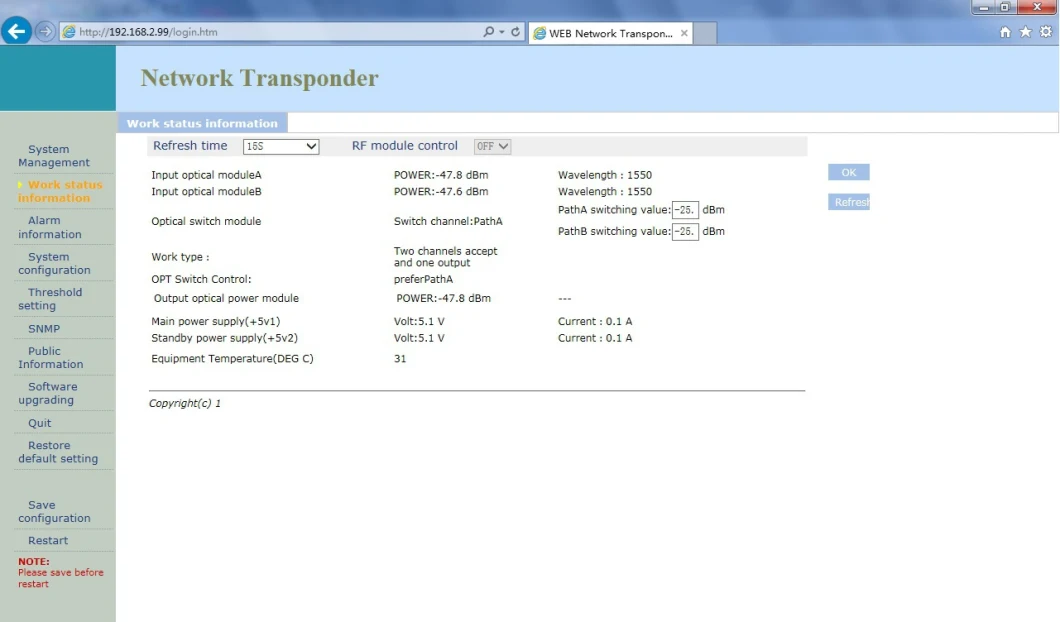

It supports the real-time monitoring of the optical power of main and standby devices. When the optical power falls to the set value, it can automatically switch to the backup channel through network management control and trigger an alarm. Switching thresholds can be set for the actual received optical power of two links respectively.

Under the condition that both main and standby optical signals are normal, the device supports the automatic, manual, or forced switching function of the optical circuit.

Rf monitoring shall be carried out in the main and standby optical signals. If a certain rf signal is lost, it will automatically switch to the normal channel.

The excellent technical performance of ultra-short switching time: fast response time, switching time less than 10ms, keeping the electro-optical circuit off.

With the radiofrequency detection function, when the main road has an optical signal but no radio frequency signal, the network management can timely alarm.

International and domestic standard SNMP Over IP Ethernet interface, remote network management; The reference threshold of switching action and the switch of the optical route should be set in the network management system. Monitoring parameters include optical routing status, input and output signal power, etc.

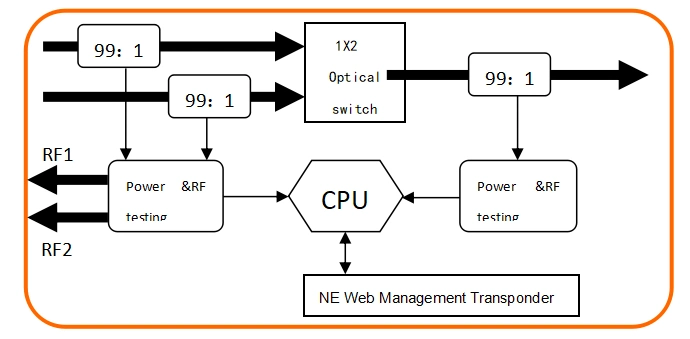

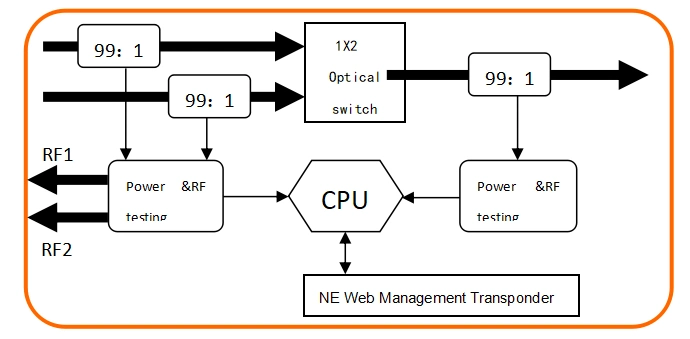

3.The principle diagram

4.Operation Instruction

5.Operation Instruction

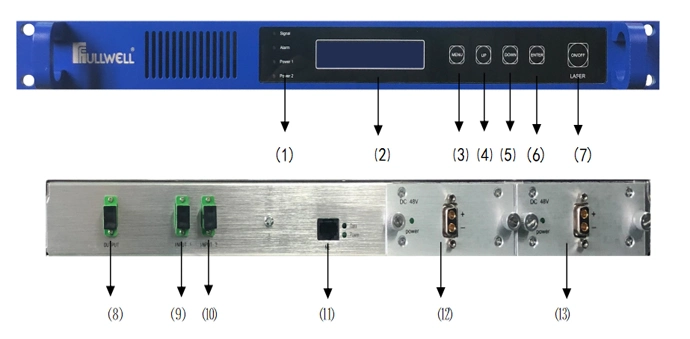

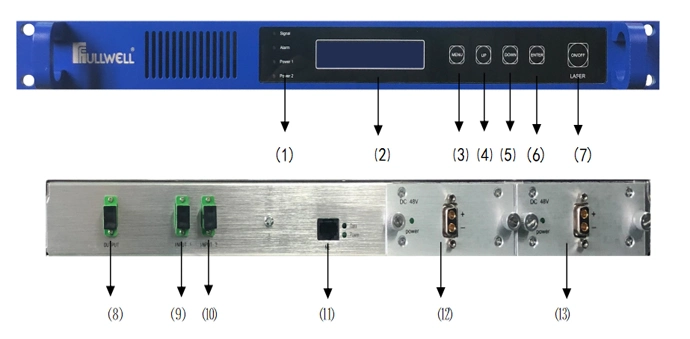

5.1 FWSW-2x1 Optical path selector Function description of front panel and back panel

Indicator(1.Input Optical Power Alarm,2.STATUS,3.Power Supply1,4.Power Supply2),LCD Display,MENU Main Menu Button,UP Button,DOWN Button, ENTER Confirm ButtonLaser Lock Switch,Optical Signal Output,CATV(1550) Optical signal input port1,CATV(1550) Optical signal input port2,NET Web Management Transponder,Module Power Supply2(DC48V),Module Power Supply1(DC48V).

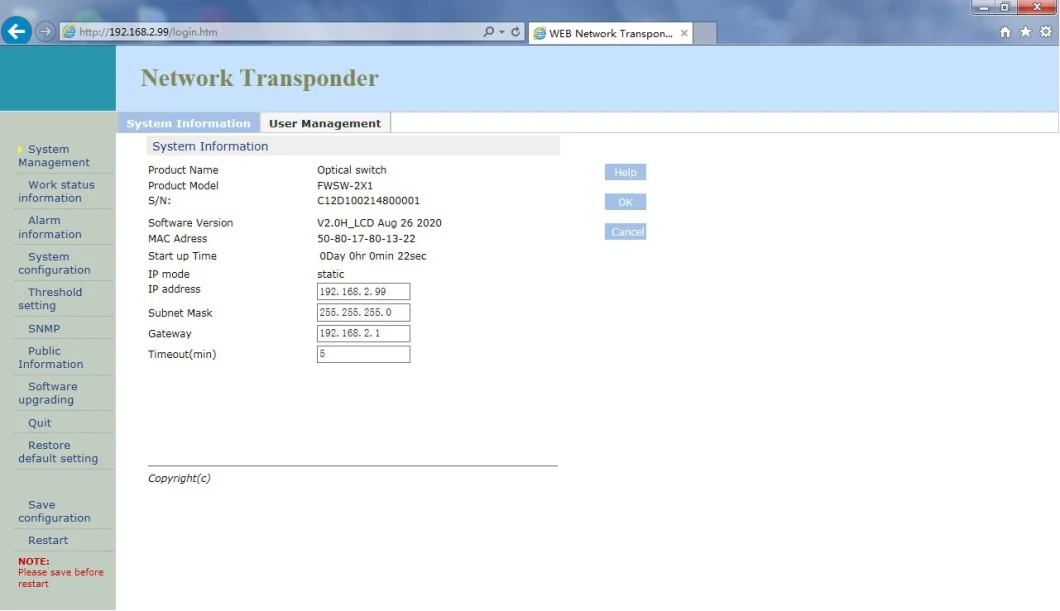

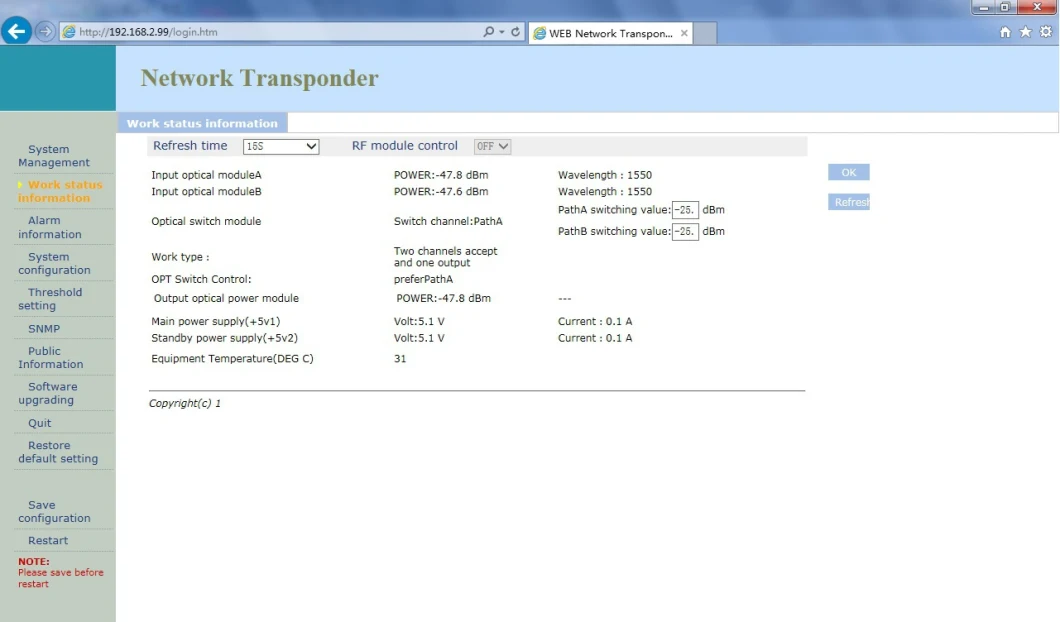

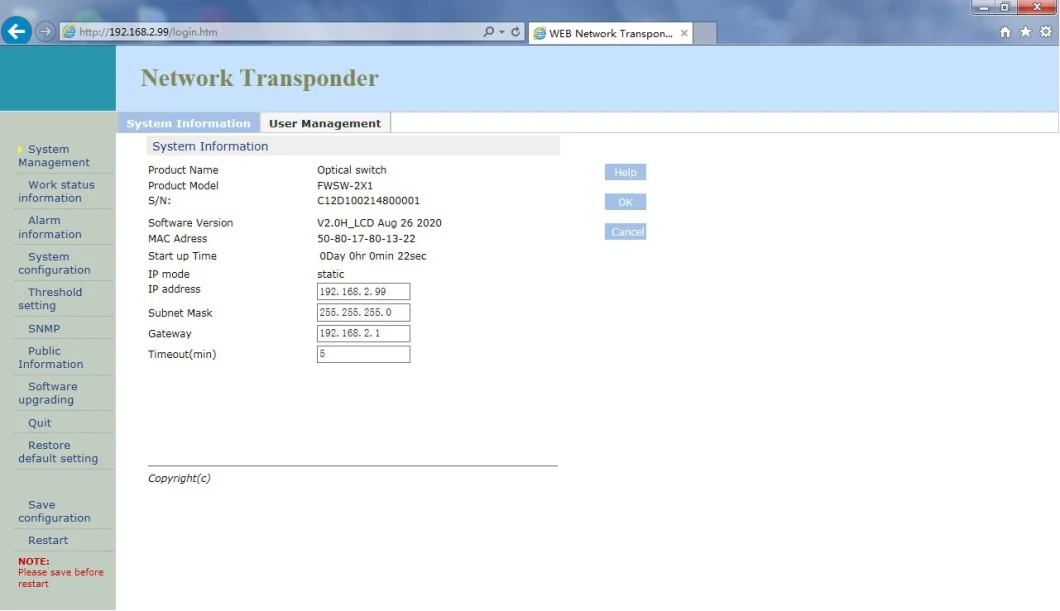

6.Application of network management System

The machine with functions of network management, light path selector network IP address set of steps to set up the IP address, just pick up the signals to RJ45 interface in the local area network (Ethernet), and then from any front-end ports connected to the main server in the local area network (LAN), the network management master server (PC) is installed on the standard of HFC network equipment management system application software, when you run the network management system can real-time monitoring the machine running status.

7 The notes about the optical connection

7. 1) before you connect them, carefully cleaning all the fiber optic connectors and connectors

Cleaning Guide:

7.1.1) Fiber Optic jumper

Removal of the dust cap of fiber optic connector, pay attention to confirm the optical connector is an APC surface;

The tips of cleaning fiber optic connector are to use a dedicated and dry cloth without velveteen (the company 5Kimwipes ®'s fine cloth); In addition, preferably adopt a special microscope (at 100 times, 200 times) to check the cleanliness of fiber optic connector surface or blemish.

pay attention to maintaining the fiber optic connectors is clean;

fiber optic connectors (flange) is clean;

you can use a dedicated compressed gas to clean the surface of the fiber optic connector;

you can remove the dust which is less than 0.2 microns, better without residue;

hold the tank of compressed air from the connector about 6 inches, alignment flange, and press the nozzle switch shortly times, so you can clean the connector completely;

if there is no dedicated compressed air, the 2.5 mm cotton swab for cleaning can also be used to clean the optical transmitter connectors, or remove the flange and clean the other side of the optical fiber jumper connector directly ;

Note: When handling fiber optic connectors must be very careful to avoid damage.

7.1.2) using the optical fiber jumper to connect the output of the optical transmitter to the optical power meter;

7.1.3) Using the optical power meter to check the output of the transmitter optical power is within normal limits;

8 Other notes

8.1) The machine should have a good grounding, grounding resistance should be smaller than 4Ω. According to international standards, the DC-48 line adopts the three-wire system, the midline is grounding wire.

8.2) The machine should be set up in an anti-hot, anti-cold, anti-wet environment, so as to avoid excessive temperature and humidity affect the useful life of the machine.

8.3) The machine adopts a high-performance, highly reliable switching power supply with constant voltage and over-current protection. In the right of switching power supply, there is 1A imported fuse that can be work at DC-48 electrical line.

8.4) To ensure the optical return loss ≥ of 45dB, this machine's optical connectors adopt SC / APC, other models (such as SC / PC) could not be picked. The connector should be installed to keep it clean. You should use ethanol and defatted cotton wool to wipe after the plug repeatedly.

8.5) Once the laser transmitter enters the work state because the light signal input(pump light input) is quite high light output for pump light, the eye cannot look directly at the light input from the back panel of the machine in order to avoid the laser beam burning the human eye retina.

9 The scope of the product warranty

The company's quality assurance system includes equipment testing and inspection of operational procedures to ensure the reliability of product quality. Prior to the product exporting from the Company, we adopt all possible measures to make the electrical, optical, mechanical and other indicators of products reached the standards promulgated. The Company requires the user to monitor on-site inspection and assembly; the testing personnel should carry out related operations in strict accordance with the preventive measures formulated when they operate and test optical static sensitive devices.

9.1) Warranty Rules

For user's first-hand products, the company repairs them in the area of materials and manufacturing processes free in a year since users pick up them.

Using this product, please follow the requirements on the instructions strictly, do not arbitrarily change. In the warranty period, the user can not break the seal, and the internal circuitry cannot be changed. If the product fails to reach the quality requirements or experience problems to be solved, please return the products to the company, which will handle according to the warranty provisions.

In the warranty period, users have the right to repair or replace the defective product confirmed by the company. However, the above provision is considered invalidly to change ownership or the irregularities caused by use, storage, transport, assembly, or accidents.

9.2) Assurance for a specific product and guide to repair

All products are produced according to high-quality standards to ensure that avoid failures in technology, materials and external framework, etc. If requests maintenance or return faulty equipment, the user should raise within 30 days on receipt of goods or in the warranty period, please follow the following principles:

9.2.1) You shall return them after you receive the Recycling Single issued by the company's sales department. When you apply a return, please attach the device model, serial number, and return reasons, and requested prepay the return shipping. If you do not pay the freight in advance nor recycling single, the Company will not receive it.

9.2.2) Before the repair, the Company will inform the user about the equipment test results and maintenance costs (generally about the failure caused by the users or issues which do not meet the warranty conditions). If the returned facilities fully meet the quality requirements and don't need to repair, or the user does not require repairs outside of warranty service, users have to pay the basic fee. Only when the user acknowledges all the costs of maintenance, the company will carry out repairs. Similarly, only with the user's consent, the company will be able to replace equipment parts (such as connectors), which is very necessary to the company's testing and repair.

9.2.3) Maintained product has the same guarantee and has guarantee benefit within90 days after picking up the purchase.

"Design and manufacture the most reliable and efficient FTTH CATV equipment products in the industry."

FWSW-2x1 optical path selector (commonly known as an optical switch) is mainly used as the protection mechanism of optical fiber networking in optical networks. In addition to low loss, it provides a good switching design in terms of an optical switch, making the switching speed of the optical switch lower than 10ms. At the same time, considering whether the optical signal RF signal monitoring and automatic switching and alarm. The front panel LCD section will provide real-time QAS monitoring parameters and alarm information, as well as some functions and parameters that can be set. In addition, the front panel LED indicator light provides a real-time alarm display.

2.Features

It supports the real-time monitoring of the optical power of main and standby devices. When the optical power falls to the set value, it can automatically switch to the backup channel through network management control and trigger an alarm. Switching thresholds can be set for the actual received optical power of two links respectively.

Under the condition that both main and standby optical signals are normal, the device supports the automatic, manual, or forced switching function of the optical circuit.

Rf monitoring shall be carried out in the main and standby optical signals. If a certain rf signal is lost, it will automatically switch to the normal channel.

The excellent technical performance of ultra-short switching time: fast response time, switching time less than 10ms, keeping the electro-optical circuit off.

With the radiofrequency detection function, when the main road has an optical signal but no radio frequency signal, the network management can timely alarm.

International and domestic standard SNMP Over IP Ethernet interface, remote network management; The reference threshold of switching action and the switch of the optical route should be set in the network management system. Monitoring parameters include optical routing status, input and output signal power, etc.

3.The principle diagram

4.Operation Instruction

| Items | Unit | Performance Index |

| Optical Operating Wavelength | nm | 1250~1610 |

| Input Optical Power Range | dBm | -15~+24 |

| Total insertion loss | dB | <1.2(Includes input/output connector losses) |

| Optical return loss | dB | >55 |

| Polarization dependent loss | dB | <0.1 |

| Switch Time | ms | <15 |

| Switching life | time | >1000000 |

| Repetitive | dB | ±0.02 |

| Crosstalk characteristics | dB | <-60(Enter isolation between A and B) |

| Wavelength dependent loss | dB | <0.1 |

| Switching optical power threshold range | dBm | -15~10/10~24 |

| Optical power input dynamic range | dB | >50 |

| Monitor light intensity accuracy | dB | ± 0.5 |

| Monitor light intensity resolution | dB | 0.1 |

| The internal network management unit | / | RJ45(following national network management standard, supports WEB) |

| Communication interface | / | RJ45 |

| Connector type | / | SC/APC |

| Working voltage | V | DC-48/20(hot-plugging single power) |

| The machine power consumption | W | <10(Dual power supply operating < 15) |

| Operating temperature/storage temperature | ºC | -20~+55/-30~+70 |

| Work and store relative humidity | % | 5~95 |

| Case Size | " | 19" 1RU |

5.Operation Instruction

5.1 FWSW-2x1 Optical path selector Function description of front panel and back panel

Indicator(1.Input Optical Power Alarm,2.STATUS,3.Power Supply1,4.Power Supply2),LCD Display,MENU Main Menu Button,UP Button,DOWN Button, ENTER Confirm ButtonLaser Lock Switch,Optical Signal Output,CATV(1550) Optical signal input port1,CATV(1550) Optical signal input port2,NET Web Management Transponder,Module Power Supply2(DC48V),Module Power Supply1(DC48V).

6.Application of network management System

The machine with functions of network management, light path selector network IP address set of steps to set up the IP address, just pick up the signals to RJ45 interface in the local area network (Ethernet), and then from any front-end ports connected to the main server in the local area network (LAN), the network management master server (PC) is installed on the standard of HFC network equipment management system application software, when you run the network management system can real-time monitoring the machine running status.

7 The notes about the optical connection

7. 1) before you connect them, carefully cleaning all the fiber optic connectors and connectors

Cleaning Guide:

7.1.1) Fiber Optic jumper

Removal of the dust cap of fiber optic connector, pay attention to confirm the optical connector is an APC surface;

The tips of cleaning fiber optic connector are to use a dedicated and dry cloth without velveteen (the company 5Kimwipes ®'s fine cloth); In addition, preferably adopt a special microscope (at 100 times, 200 times) to check the cleanliness of fiber optic connector surface or blemish.

pay attention to maintaining the fiber optic connectors is clean;

fiber optic connectors (flange) is clean;

you can use a dedicated compressed gas to clean the surface of the fiber optic connector;

you can remove the dust which is less than 0.2 microns, better without residue;

hold the tank of compressed air from the connector about 6 inches, alignment flange, and press the nozzle switch shortly times, so you can clean the connector completely;

if there is no dedicated compressed air, the 2.5 mm cotton swab for cleaning can also be used to clean the optical transmitter connectors, or remove the flange and clean the other side of the optical fiber jumper connector directly ;

Note: When handling fiber optic connectors must be very careful to avoid damage.

7.1.2) using the optical fiber jumper to connect the output of the optical transmitter to the optical power meter;

7.1.3) Using the optical power meter to check the output of the transmitter optical power is within normal limits;

8 Other notes

8.1) The machine should have a good grounding, grounding resistance should be smaller than 4Ω. According to international standards, the DC-48 line adopts the three-wire system, the midline is grounding wire.

8.2) The machine should be set up in an anti-hot, anti-cold, anti-wet environment, so as to avoid excessive temperature and humidity affect the useful life of the machine.

8.3) The machine adopts a high-performance, highly reliable switching power supply with constant voltage and over-current protection. In the right of switching power supply, there is 1A imported fuse that can be work at DC-48 electrical line.

8.4) To ensure the optical return loss ≥ of 45dB, this machine's optical connectors adopt SC / APC, other models (such as SC / PC) could not be picked. The connector should be installed to keep it clean. You should use ethanol and defatted cotton wool to wipe after the plug repeatedly.

8.5) Once the laser transmitter enters the work state because the light signal input(pump light input) is quite high light output for pump light, the eye cannot look directly at the light input from the back panel of the machine in order to avoid the laser beam burning the human eye retina.

9 The scope of the product warranty

The company's quality assurance system includes equipment testing and inspection of operational procedures to ensure the reliability of product quality. Prior to the product exporting from the Company, we adopt all possible measures to make the electrical, optical, mechanical and other indicators of products reached the standards promulgated. The Company requires the user to monitor on-site inspection and assembly; the testing personnel should carry out related operations in strict accordance with the preventive measures formulated when they operate and test optical static sensitive devices.

9.1) Warranty Rules

For user's first-hand products, the company repairs them in the area of materials and manufacturing processes free in a year since users pick up them.

Using this product, please follow the requirements on the instructions strictly, do not arbitrarily change. In the warranty period, the user can not break the seal, and the internal circuitry cannot be changed. If the product fails to reach the quality requirements or experience problems to be solved, please return the products to the company, which will handle according to the warranty provisions.

In the warranty period, users have the right to repair or replace the defective product confirmed by the company. However, the above provision is considered invalidly to change ownership or the irregularities caused by use, storage, transport, assembly, or accidents.

9.2) Assurance for a specific product and guide to repair

All products are produced according to high-quality standards to ensure that avoid failures in technology, materials and external framework, etc. If requests maintenance or return faulty equipment, the user should raise within 30 days on receipt of goods or in the warranty period, please follow the following principles:

9.2.1) You shall return them after you receive the Recycling Single issued by the company's sales department. When you apply a return, please attach the device model, serial number, and return reasons, and requested prepay the return shipping. If you do not pay the freight in advance nor recycling single, the Company will not receive it.

9.2.2) Before the repair, the Company will inform the user about the equipment test results and maintenance costs (generally about the failure caused by the users or issues which do not meet the warranty conditions). If the returned facilities fully meet the quality requirements and don't need to repair, or the user does not require repairs outside of warranty service, users have to pay the basic fee. Only when the user acknowledges all the costs of maintenance, the company will carry out repairs. Similarly, only with the user's consent, the company will be able to replace equipment parts (such as connectors), which is very necessary to the company's testing and repair.

9.2.3) Maintained product has the same guarantee and has guarantee benefit within90 days after picking up the purchase.

"Design and manufacture the most reliable and efficient FTTH CATV equipment products in the industry."